top of page

Repairs

-

Ring Sizing

-

Watch Battery Replacement

-

Chain Soldering

-

Solder Wedding Set Together

-

Replace missing stones

-

Replace clasps

-

Refurbish any jewelry

-

Retip/Replace Prongs

-

Replace Heads

-

Jump Rings

-

Solder shank

-

Rhodium Plating

-

Attach safety chains

-

Tighten Stones

-

Repair Rivets

-

Shorten Watch Bands

-

Set Stones

-

Recut Stones

-

Eye glass Repair

-

Epoxy Pearls

-

Channel repair (channel set stones)

Often we will repair things that others won't even try! Feel free to stop in or to call with any questions or concerns.

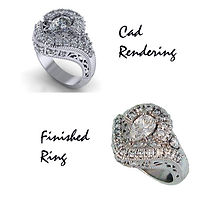

Matrixgold Cad: At HTG Design Jewelers, we use the MatrixGold Cad program software, one of the most advanced computer aided design programs available. In this process the jewelry is first designed on the computer. The design process is shared with the customer through computer rendered images which can be viewed from numerous angles and even rotated 360° to see all surfaces. Once the design is approved, a 3D model is produced through milling or 3D printing. The model is then cast, cleaned, polished and the stones set. Here are pictures of the computer rendering and the finished piece of jewelry:

Hand Fabrication: For this process the jewelry is created, start to finish, at the jewelers bench. Precious metals and various findings are formed and fabricated, then soldered together. Diamonds and gemstones are set and the end result is something that might look like this:

Hand Carved Wax Models: In this process, a design is agreed upon, and the goldsmith carves it from wax. When the wax model is complete, the customer comes in for a viewing. On approval, the wax is cast through a process called ‘lost wax casting’. The cast metal is then cleaned and polished, stones are set and the entire piece is given a final polish. Your end result would look like this:

Appraisals

Often, your home insurer will require an appraisal of your valuable jewelry to determine the retail replacement value, new, of your particular piece of jewelry. This appraisal is to function as a value estimate for obtaining insurance. The value is representative of the time it is accomplished and the regional market.

Retail replacement, new, is defined as the value that is the mode of current sales in the most common and appropriate market for new, like kind, or comparable jewelry. The valuation of the appraised piece is the replacement value at the current date in the local marketplace.

A variety of sources are consulted to obtain the value. The specific market addressed is the one in which the jewelry is most commonly sold to consumers by retailers in new condition, a retail jewelry establishment.

Measurements of all gemstones and weights are estimates. They are formulated using accepted industry standards. All diamond and gemstone grading reflects the grading standards of the Gemological Institute of America. All jewelry evaluations and appraisals are subjective, and estimates of value may vary.

Quality analysis of gemstones is limited by various types of settings, mountings, and lighting conditions. The quality grades might differ if analyzed removed from the mountings, or under different light sources. Metals are identified by electronic testing. Designer and manufacturer is identified from trademarks, hallmarks, or maker’s marks, if present. Considerations in the final estimate of value include quality grading of diamonds and gemstones, metal karatage and weight, designer/artist/manufacturer, type of manufacture, quality of craftsmanship, design, physical condition, repairs needed or performed, supply and demand, and economic conditions of the current jewelry market.

The value expressed is based on current market information and no opinion is expressed as to any long range or future value, nor as to any past value. The appraiser has no present or future interest in the purchase and/or resale of the property appraised and the fee for this appraisal is not contingent upon values submitted.

The cost of an appraisal is $80 per piece.

Services

bottom of page